Technology and Expertise

Designing Better Materials with Engineering and Skills

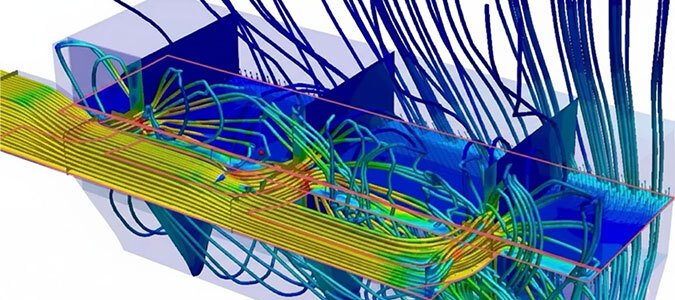

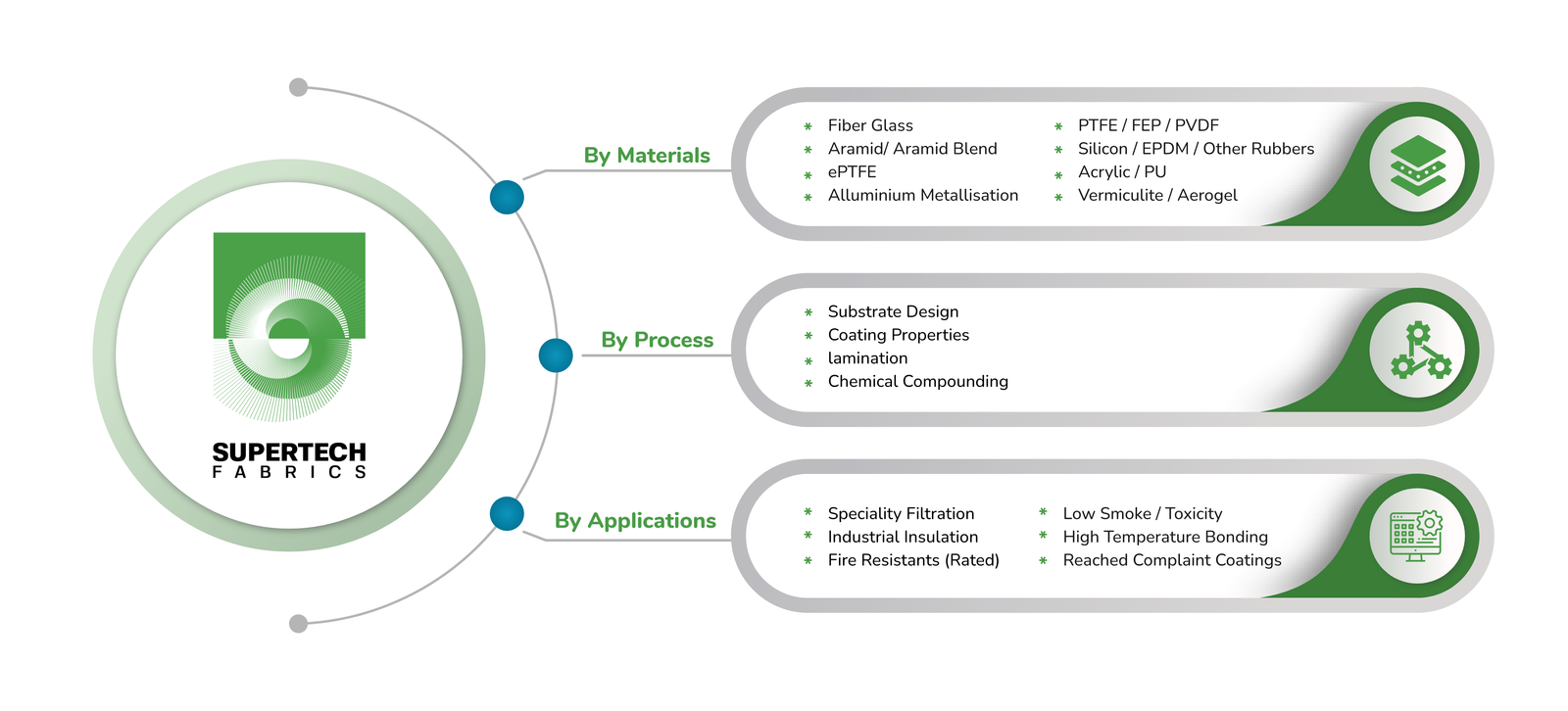

Our state-of-the-art facility, led by experienced specialists, utilises high-grade raw materials such as glass fibre, aramids, technical polymers, and functional additives. These materials are processed with precision using the latest coating, dipping, and lamination technologies to achieve consistent quality and performance across every production line.

We offer a versatile portfolio of surface-engineered materials featuring PTFE, silicone, neoprene, PU, PVC, vermiculite, and aerogel coatings, available in widths up to 2.5 metres. Multi-layered composites are produced through advanced calendaring, hot-melt lamination, and thermal bonding systems, enabling superior structural integrity and uniformity across applications.

Our approach is rooted in functional engineering. Each material is designed to meet specific performance requirements—whether thermal resistance, chemical stability, flexibility, or flame retardancy—and then manufactured through optimised process flows to ensure reliability in demanding operating environments.

We operate in accordance with globally recognised standards, including ISO 9001 for Quality Management, ISO 14001 for Environmental Management, and ISO 45001 for Occupational Health and Safety, along with CE Marking for product compliance and REACH certification for chemical safety.

- SUBSTRATE DEVELOPMENT.

- WEAVING.

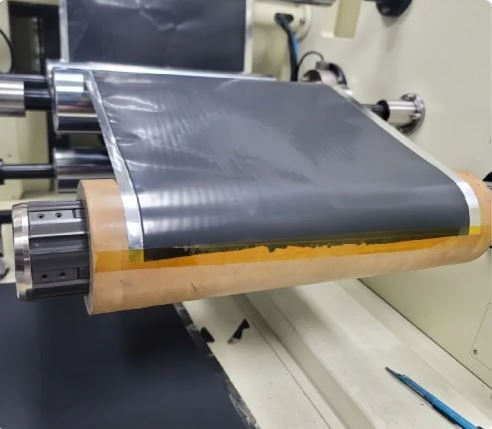

- KNIFE COATING.

- WATER / SOLVENT COATING.

- FOAM COATING.

- DIP COATING.

- PADDING COATING.

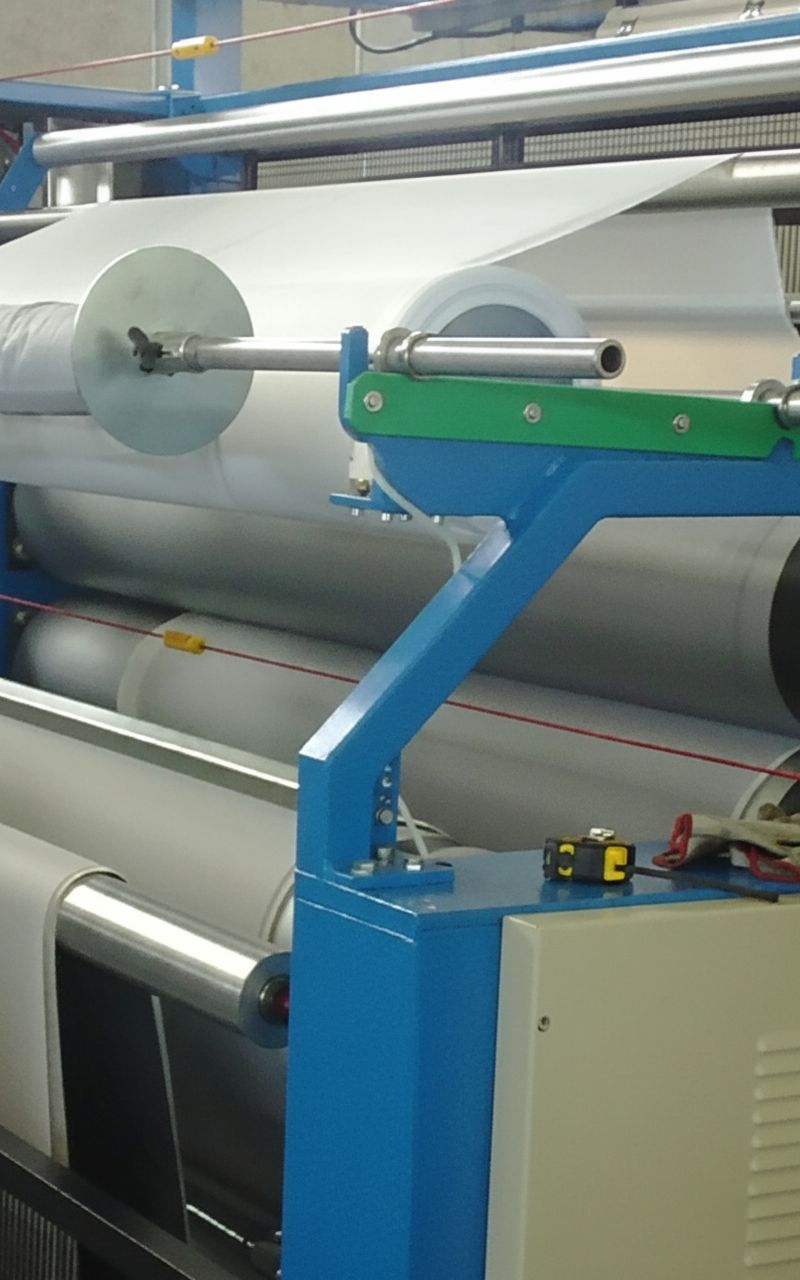

- FILM LAMINATION.

- MEMBRANE LAMINATION.

- EMBOSSING AND ATTENING.

- HOT / COLD CALENDARING.

- SINGEING .

- SLITTING.

- WINDING.

- STITCHING.

CENTERS OF EXCELLENCE

At Supertech Fabrics, our Centre of Excellence serves as the nucleus of innovation, research, and technical advancement in high-performance textile engineering. It brings together material scientists, process engineers, and application specialists to continually push the boundaries of filtration media and engineered composites.

INNOVATION FOR PERFORMANCE

R&D Investment

5.2% Of Annual Revenue

Trials/Prototypes

20+ Annually

Lab-To-Line Conversions

90% Success Rate

At Supertech Fabrics, innovation lies at the heart of our values and drives every aspect of our work in technical textiles. While we take pride in our advanced products engineered for specialised modern applications, our pursuit of improvement is continuous — extending beyond existing solutions to redefine what is possible.

Through rigorous research and development, we pioneer new material formulations and craft high-value, performance-driven products that stand distinctly above conventional textile offerings. This dedication enables us to develop next-generation technical textiles that meet the evolving demands of specialised industries, combining uncompromising quality with superior functionality.

Our unwavering focus on innovation and excellence ensures that Supertech Fabrics remains at the forefront of engineering the solutions of tomorrow.